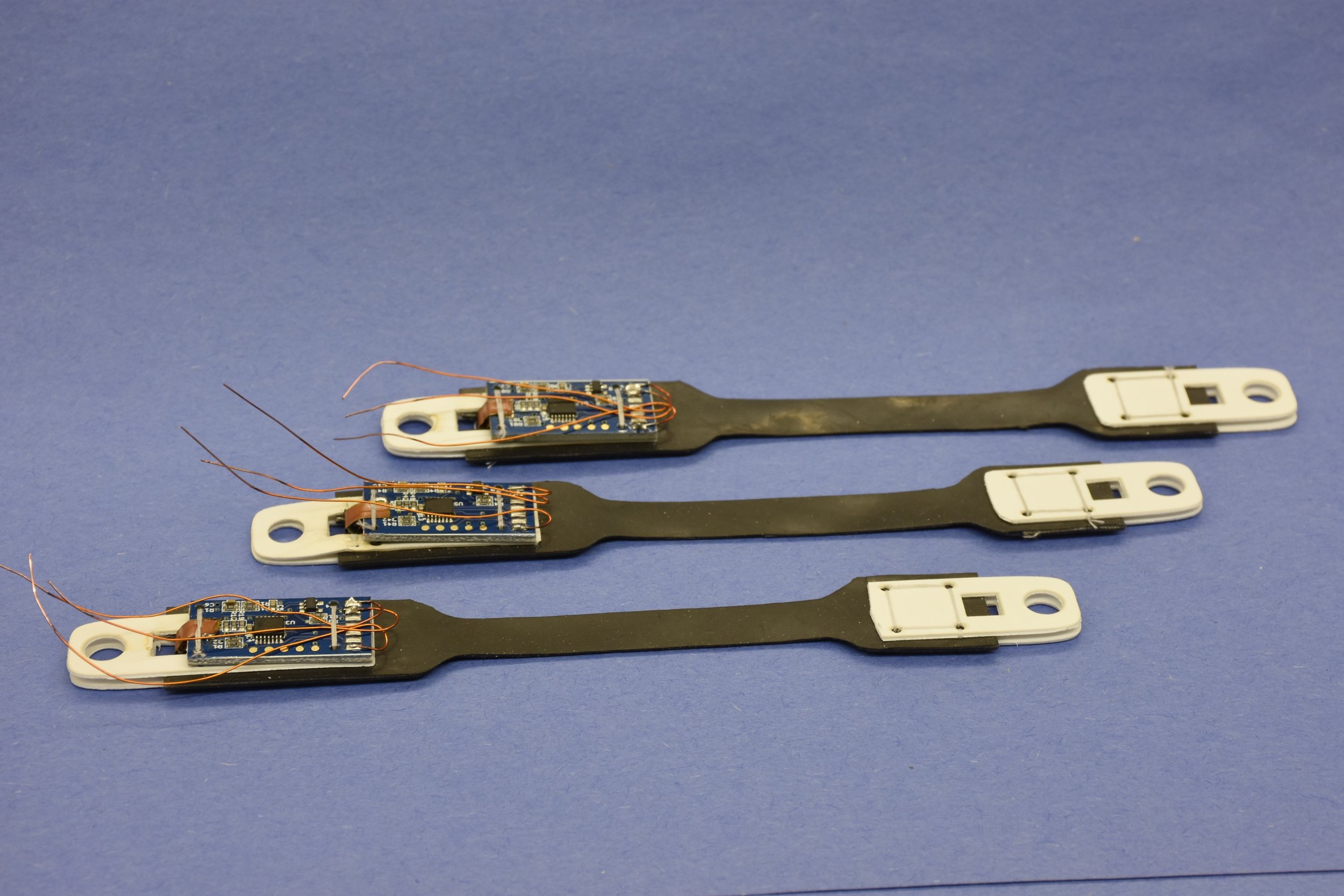

Building capacitive strain sensors.

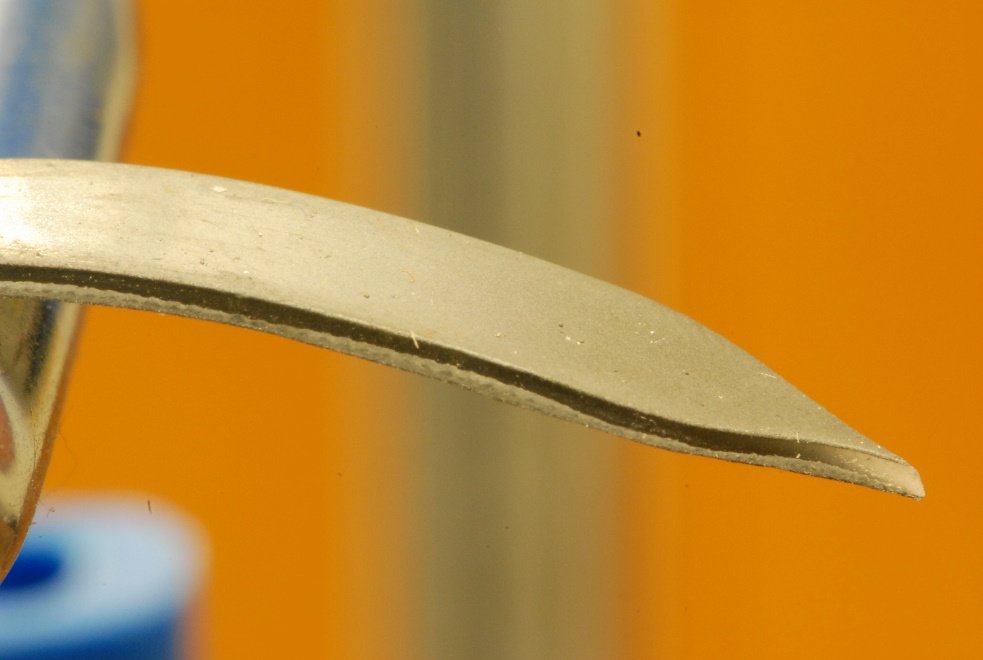

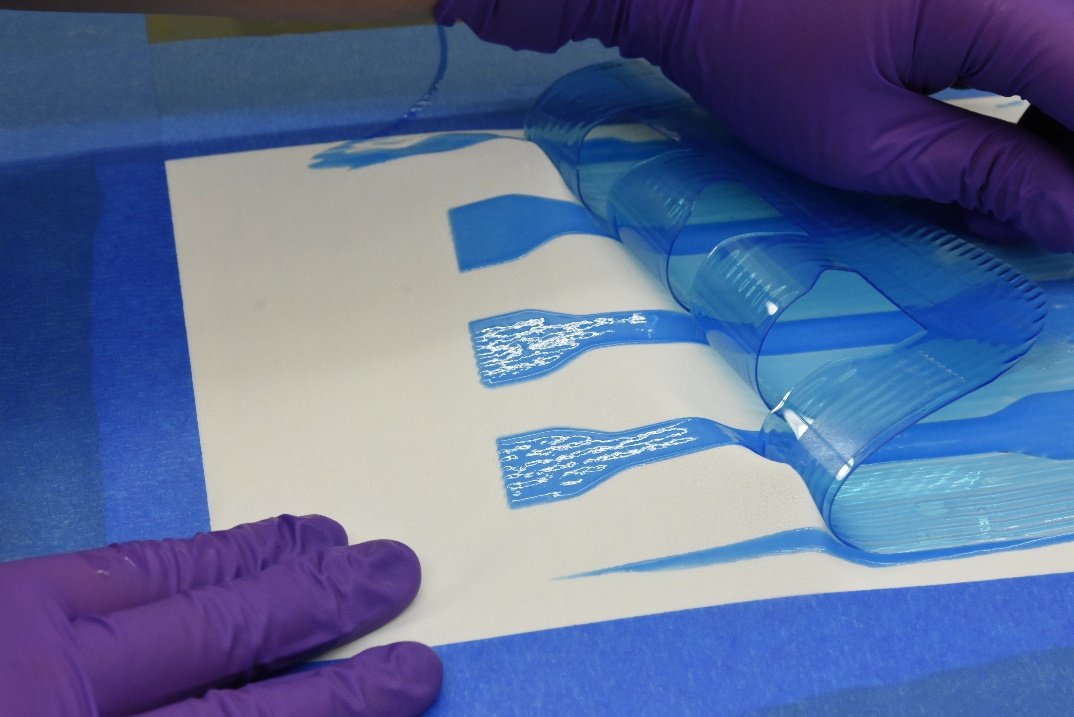

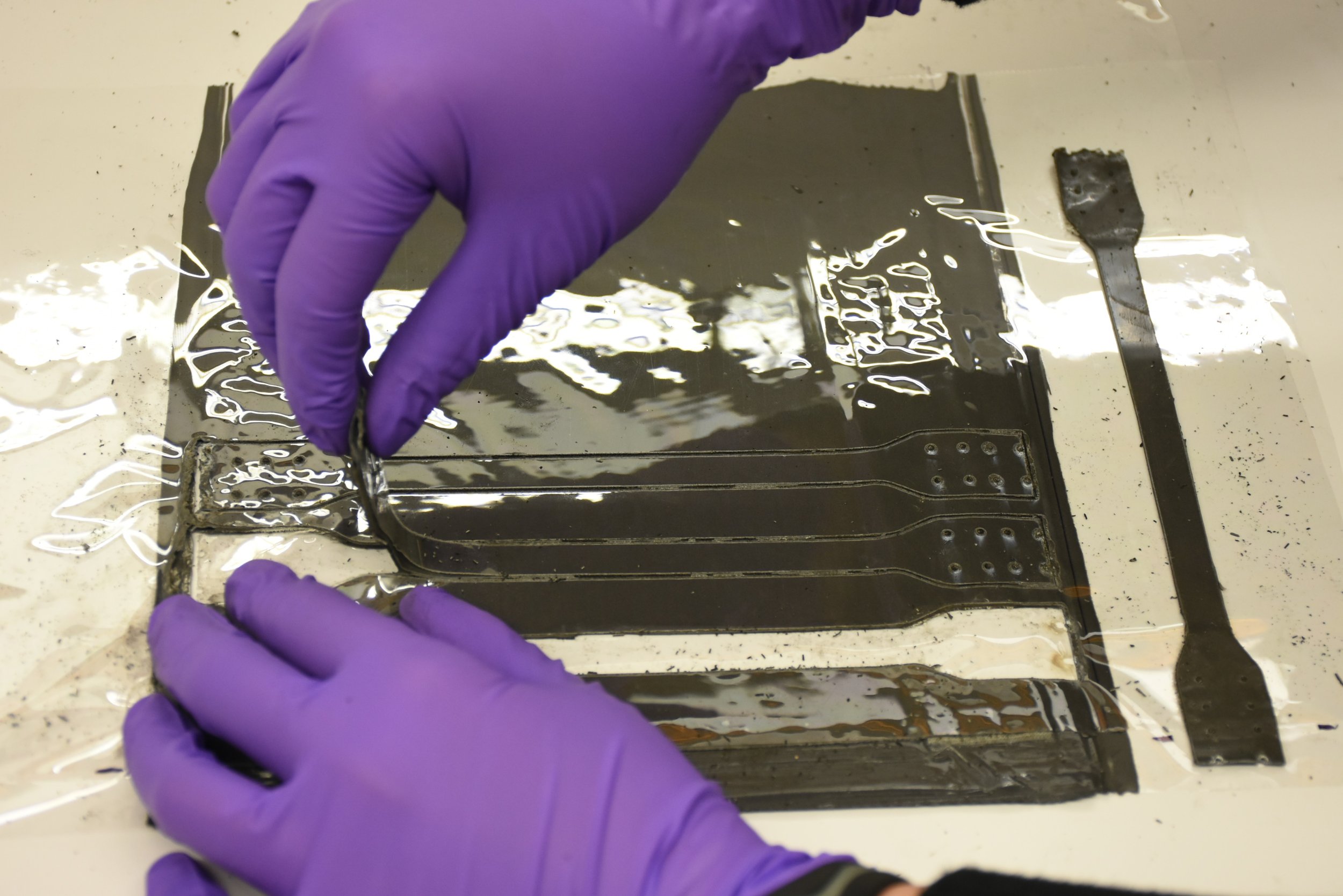

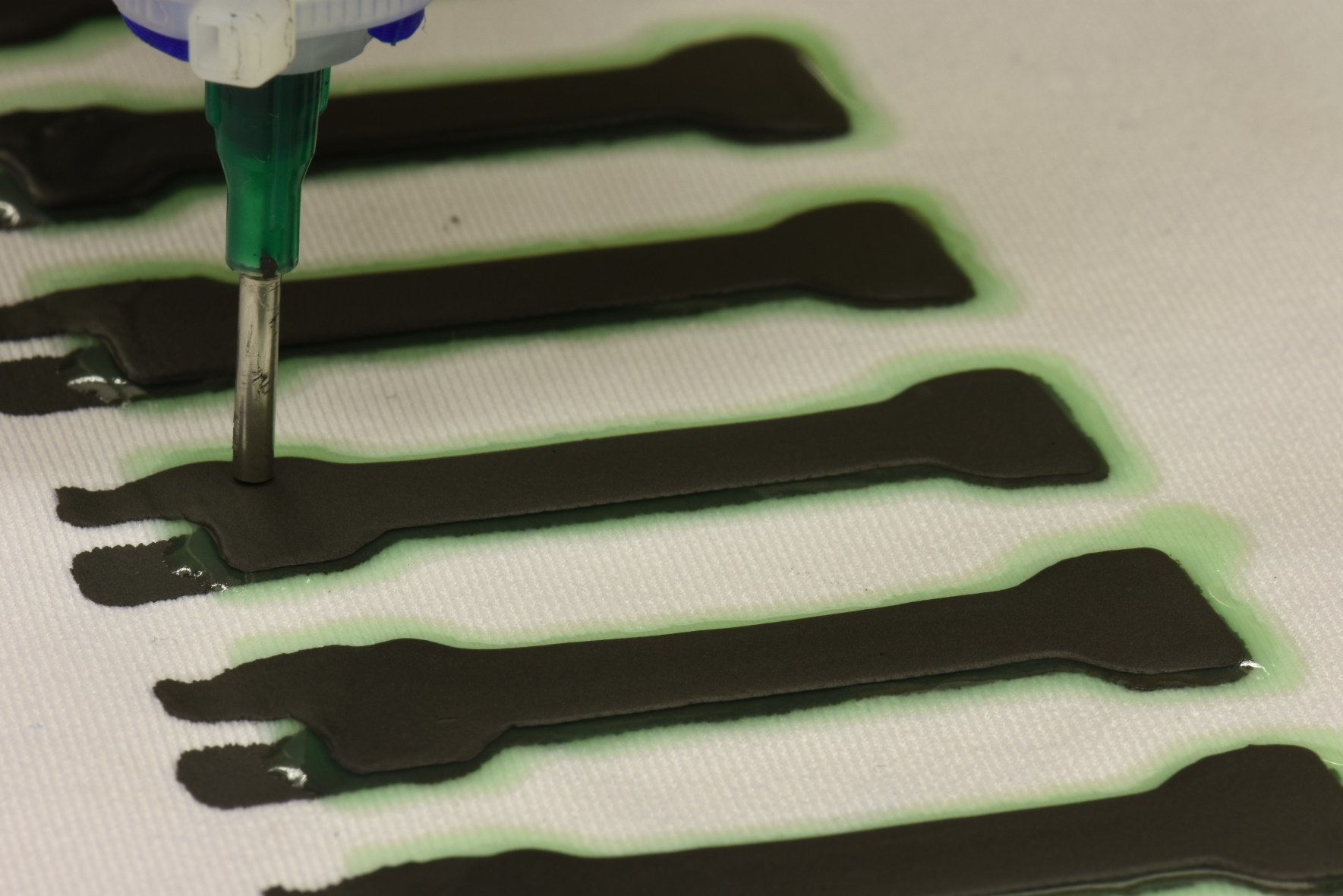

The capacitive strain sensors are structured like a parallel plate capacitor — a thin non-conductive dielectric material in between two conductive plates. The materials used here include silicone elastomer for the dielectric material, and a stretchable conductive composite consisting of silicone and expanded graphite particles. We developed three manufacturing methods for fabricating these sensors: 1) scalable layer-by-layer deposition of large (30 x 60 cm) films of the constituent materials followed by laser-cutting sensor arrays, 2) stencil printing the sensors directly into fabric substrates to embed the sensor arrays, and 3) extrusion printing the materials into fabric to more precisely place sensors in the substrate. The resulting sensors were markedly robust compared to previous work, able to undergo thousands of cycles of high strain with little change in performance, and could measure strains up to 50% repeatably. These qualities led us to use these sensors in subsequent projects and with our collaborators (see below).

E.L. White*, M.C. Yuen*, J.C. Case, R.K. Kramer. "Low-cost, Facile, and Scalable Manufacturing of Capacitive Sensors for Soft Systems." Advanced Materials Technologies, Vol. 2, No. 9, 2017.

Capacitive strain sensors for soft robots and wearable applications.

These sensors have several useful characteristics for robot applications: 1) Repeatable response, 2) Physically robust, 3) Easy to integrate. These properties allowed us to deploy these sensors in robot platforms with widely different structures, applications, and materials.

J.W. Booth, D.S. Shah, E.L. White, M.C. Yuen, J.C. Case, O. Cyr-Choiniere, and R. Kramer-Bottiglio, “OmniSkins: Robotic skins that turn inanimate objects into multifunctional robots,” Science Robotics, vol. 3, no. 22, p. eaat1853, Sep. 2018.

M.C. Yuen*, R.A. Bilodeau*, J.C. Case, T.L. Buckner, and R. Kramer-Bottiglio, “Design for Control of a Soft Bidirectional Bending Actuator,” in 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), pp. 5936-5943, Madrid, Spain, 2018.

L. Chin, M.C. Yuen, J. Lipton, L. H. Trueba, R. Kramer-Bottiglio, and D. Rus, “A Simple Electric Soft Robotic Gripper with High-Deformation Haptic Feedback,” in 2019 International Conference on Robotics and Automation (ICRA), pp. 2765–2771, Montreal, Canada, 2019.

J.C.S. McCaw, M.C. Yuen, and R. Kramer-Bottiglio, “Sensory Glove for Dynamic Hand Proprioception and Tactile Sensing,” in 2018 ASME 2018 IDETC, Quebec City, Canada, 2018.

M.C. Yuen, T.R. Lear, H. Tonoyan, M. Telleria, and R. Kramer-Bottiglio “Toward Closed-Loop Control of Pneumatic Grippers During Pack-and-Deploy Operations.” IEEE Robotics and Automation Letters, vol. 3, no. 3, pp. 1402-1409, July 2018.